BIG BAG FILLING SYSTEMS

Big-Bag filling machine realizes the filling of powder and granular materials to Big-Bags by means of PLC control. Filling range can be between 250-3000 Kg. Screw feeder, belt feeder or gate valve can be used according to the material characteristics. For powder materials screw feeder is preferred to minimize dust spread, while belt feeder is used for granular materials. Big-Bag is hanged to the machine from its four loops by the operator and desired filling value is adjusted from the OP. Pressing the start button starts the filling.

In order to use the whole volume of the bag, hydraulic lifting system periodically shakes the bag and places the material homogenously into the bag. By means of the hydraulic mechanism, Big-Bag is held up above the ground to ensure maximum filling. Because the filling chute is moveable up and down, operator would not need to climb to a platform to hang the Big-Bag and to fit the spout of Big-Bag. When In order to gain accuracy slow feeding. Feeding process has two speed steps: one fast; for reducing the filling time, and one slow; for achieving accuracy. Slow and fast feeding weight values can be entered from the operator panel.

Semi Automatic Big-Bag Filling Machines

Operator hooks the lifting belts of big-bag to the machine. Again the operator takes the lifting belts off when the filling process finishes and the big-bag remains on the conveyors. Big-bag is taken away by means of a forklift. This also means that a new filling process can’t be started before the bag is taken away from the machine.

|

|

Full Automatic Big-Bag Filling Machines

Operator hooks the lifting belts of big-bag to the machine. Hooks opens automatically when the filling process finishes and the big-bag remains on the motorized conveyors. By means of this conveyor loaded big-bag is transferred to the exiting conveyor. The process repeats by attaching a new big-bag.

|

|

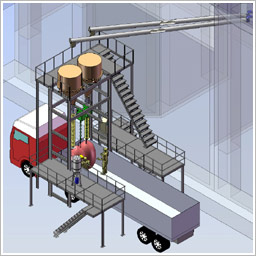

Big-Bag Filling on Truck

Big-Bag Filling on Truck is totally an evolutionary design of SAFMAK in order to meet Cement Industry needs economically. Cement filled big-bags can not stand still immediately due to air/material mixture at first; they have a risk of tilting right after filling. Instead of being filled on ground, these big-bags are filled on truck, side by side enabling the material to settle inside the big-bag while the truck travels to its destination. SAFMAK filling system can fill 1 ton big-bags in 4 minutes within %0,5 accuracy range with capacities up to 10-20 ton/hour. Filtration and dust collecting systems ensures a dust free operation while re-gaining the material.

|

|

BIG-BAG FILLING SYSTEMS EQUIPMENTS

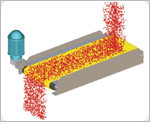

Big-Bag Feeding Equipments

Screw feeder, belt feeder or gate valve can be used according to the material characteristics. For powder materials screw feeder is preferred to minimize dust spread, while belt feeder is used for granular materials.

|

|

|

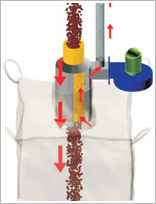

Big-Bag Forming & Suction Equipment

This option is generally used for polyethylene air proof big-bags with inside cover. After mounting the spout of the bag, a fan unit blows air into the deformed big-bag. By this way bag have a tight form, which help us in complete filling. Bag inflation air is given from outer tube. During inflation, pneumatic valve closes the vacuum line. Dusty air inside the bag will be vacuumed from the outer tube by the factories vacuum line or by optional filter unit, while the material is fed from the inner one.

|

|

Big-Bag Automatic Hooks

In this option 4 hooks, which hold lifting loops of Big-Bag, are operated by pneumatic pistons. After completion of filling, PLC system automatically opens the hooks and releases the Big-Bag, so that the filled Big-Bag is free to be transported to the exit conveyor

Conveyors

Integral and exit conveyors are used to transport the filled Big-Bags towards exit side. When conveyors are added fork-lifter can be used to take away the filled Big-Bags; otherwise the fork-lifter may damage the weighing platform.

Big-Bag Pallet Magazine Unit

This option is mounted near filling unit and suggested to buy with outlet conveyor. It will be able to store 20 pallets and to let them one by one, with pneumatic operated pistons. It consists of a storage section, pneumatic pistons and roller conveyors. Automation of this unit is in sequence with main filling machine.

Electrical Panel & PLC Automation

All the automation is controlled from the PLC unit. Operator can set and change parameters from the Operator Panel. Some of them are: Filling Value, Tolerances and Prior Cut Values in order to optimize the filling process.